Processing of functional surfaces on 3D printed parts

Generative manufacturing methods (additive manufacturing) allow the production of highly complex forms and shapes on prototypes and functional components that cannot be produced or can only be produced with great effort using conventional subtractive methods (machining by turning and milling from the solid material).

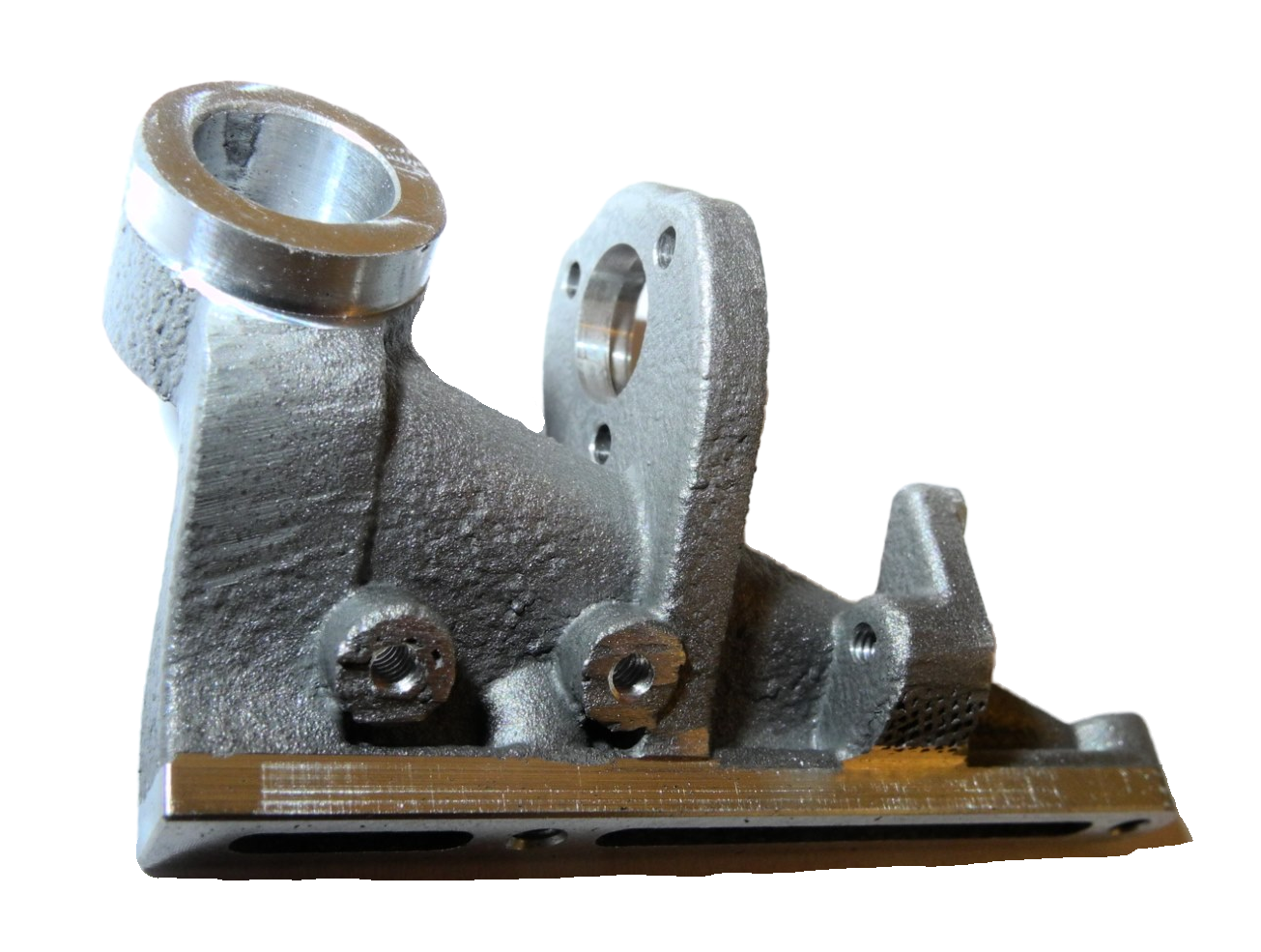

However, depending on the 3D manufacturing technology, the surface qualities and geometries are usually not precise enough for the assembly of attached parts. The required connection dimensions and tolerances on the functional and assembly surfaces are subsequently produced in a traditional way using cutting machining through turning and milling to ensure a precise mounting.

For our customers, we process externally produced 3D printing parts made of metal material so that the mechanically machined functional surfaces are prepared for further assembly.

Our precision - your success.

Our CNC machined parts and assemblies are used in industries such as aerospace, optics and medical technology. From miniature parts to heavyweights - we have the expertise and experience to meet your requirements.

Do you need support from the product idea to series production?

Put your trust in our decades of experience.

The following materials are in use:

- Aluminium

- Stainless steel

- Tool steel

- Titanium

Delivery of our precision parts to a wide range of industries:

- Aviation

- Space travel

- Medical technology

- Optical device manufacturing