Basics and techniques of milling

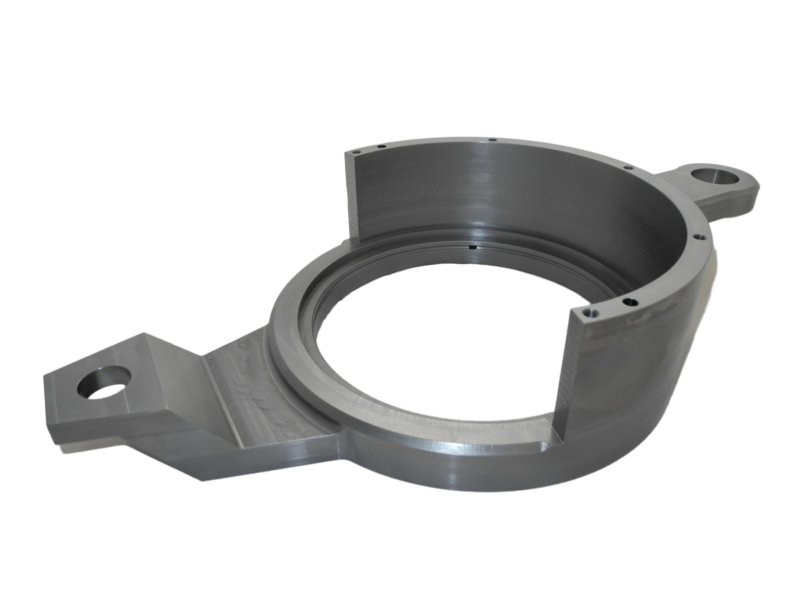

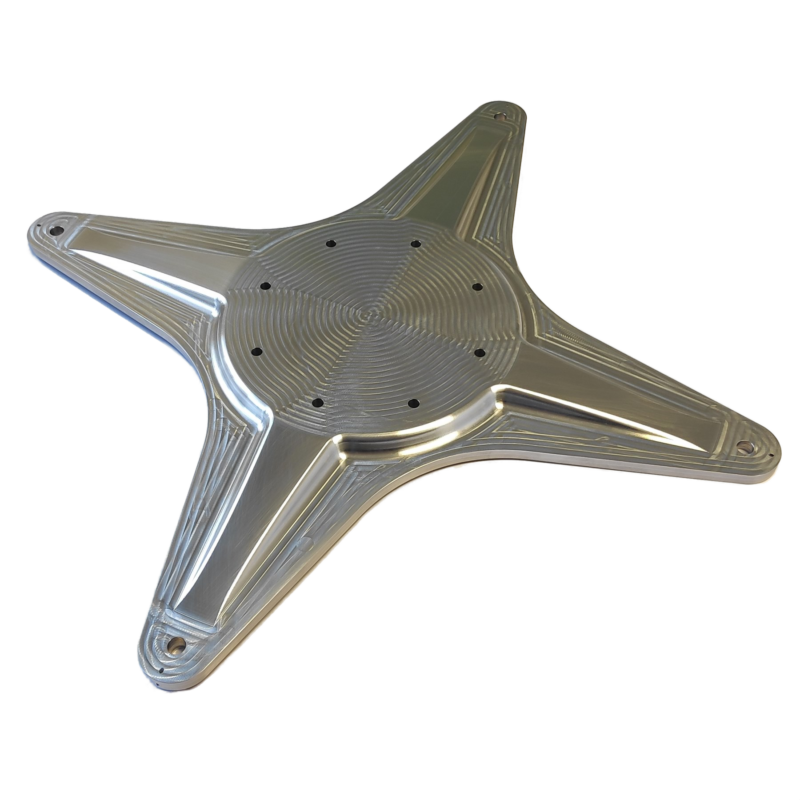

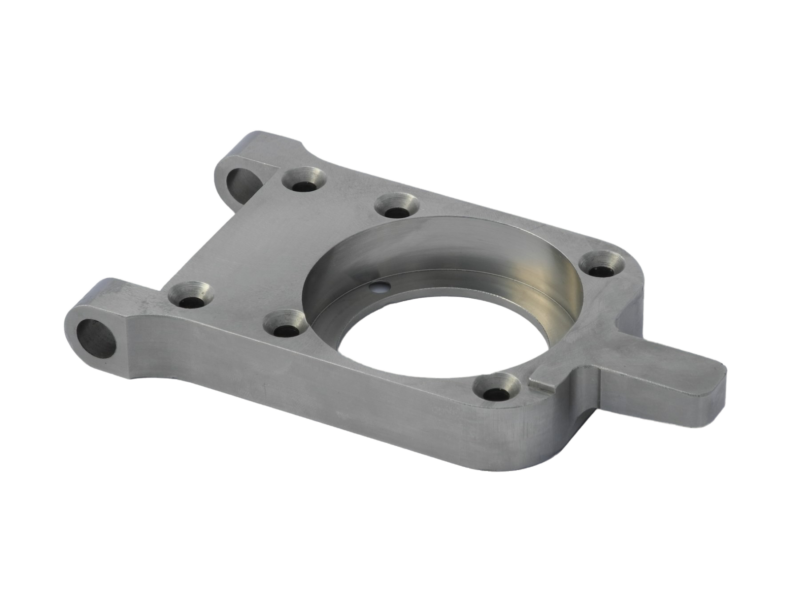

The principle of milling is a central component of modern machining production technology and enables the manufacturing of precise parts with high quality for industries such as aviation, space travel or medical technology. During milling, a workpiece that is stationary or guided on a clamping table is machined using a rapidly rotating milling tool. Flat surfaces as well as complex multi dimensional surfaces and contours can be produced using differently shaped machining tools.

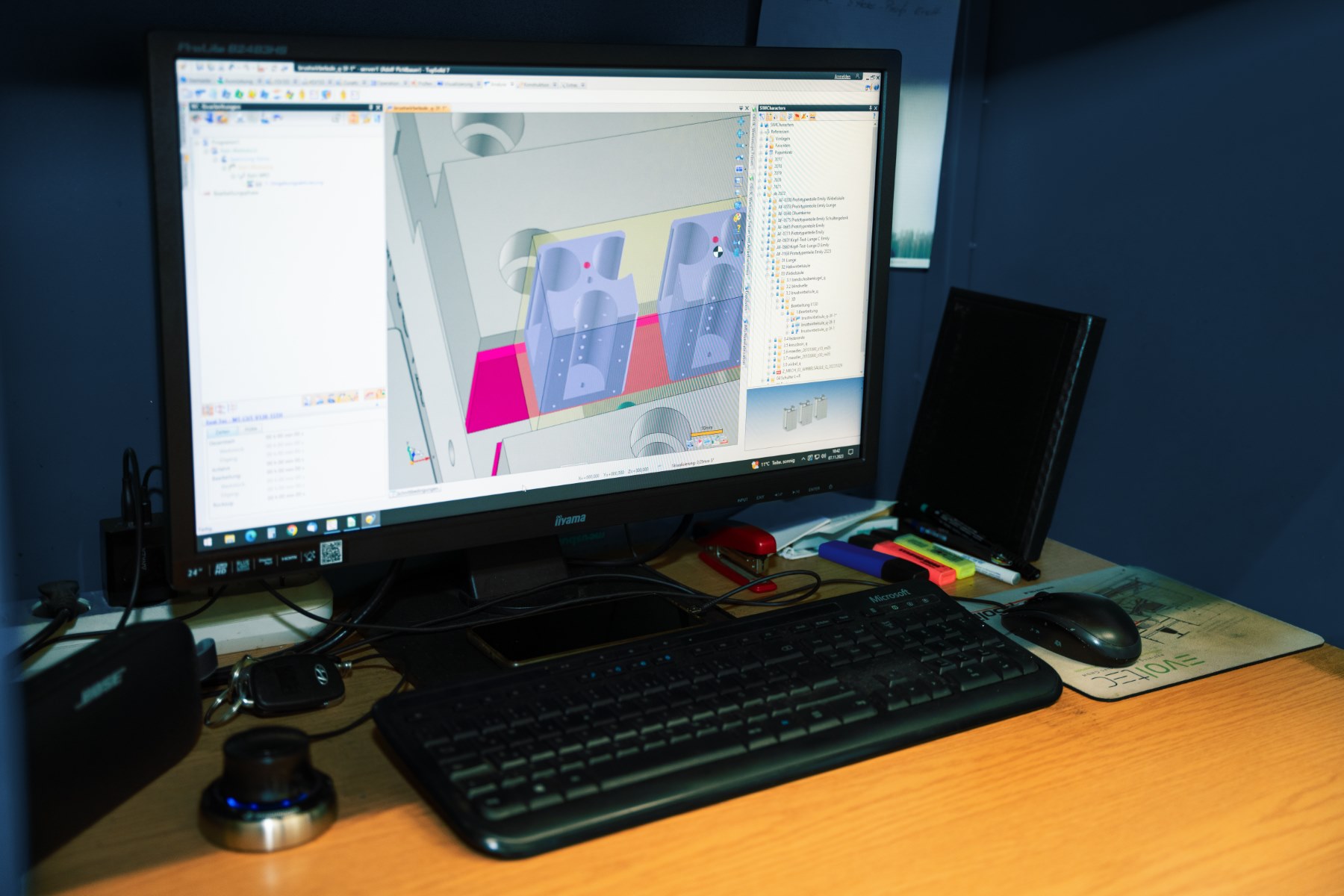

CNC milling (Computer Numerical Control) offers extraordinarily high precision and repeatable accuracy. Complex geometrical shapes with tight tolerances can be produced.

The requirements for the technical qualifications of skilled workers are particularly high. It requires a deep understanding of the technical complexity of machining technology as well as the properties of various materials. Programming and operating CNC milling machines requires extensive professional knowledge of Computer-Aided Design (CAD) and Computer-Aided Manufacturing (CAM) Software.

Continuous specialised advanced training and instruction of our employees is the basis for granting the high quality standards of our customers.

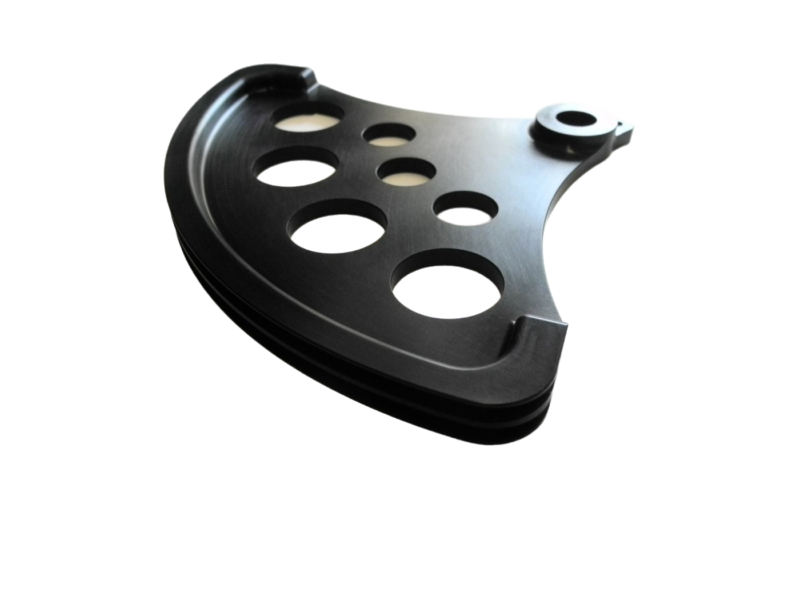

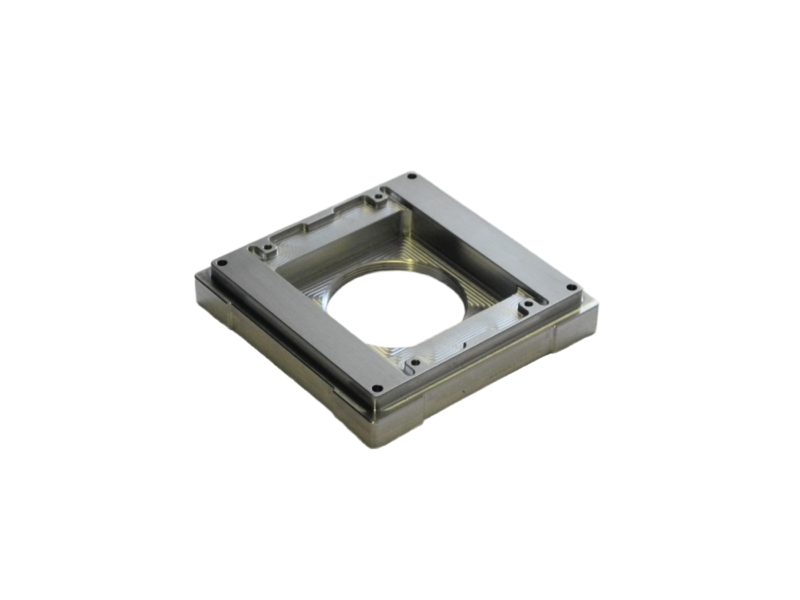

Our milled parts are manufactured on 3- and 5- axis CNC machining centres and also on conventional toolmaking milling machines.

Dimensions:

- X-axis up to 1100mm

- Y-axis up to 610mm

- Z-axis up to 610mm

Possible additional processing:

- Grinding

- Heat treatment

- Surface finishing

Our precision - your success.

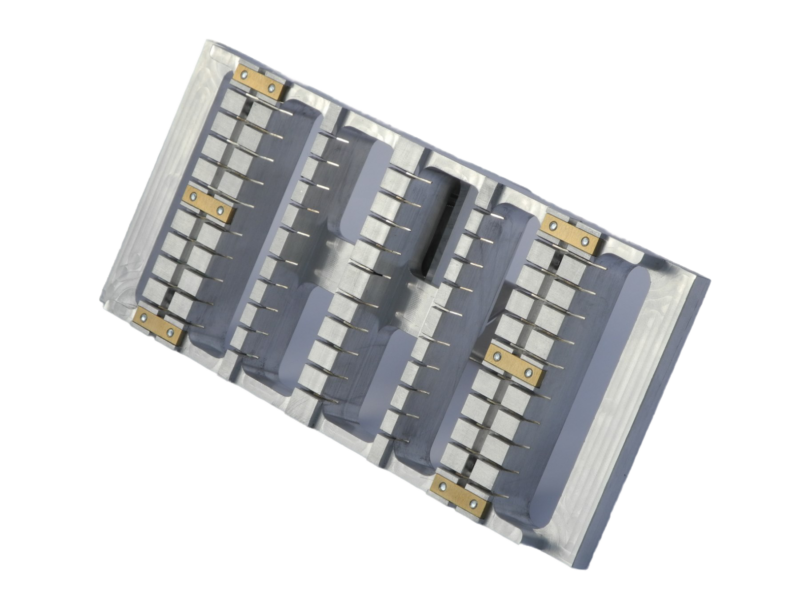

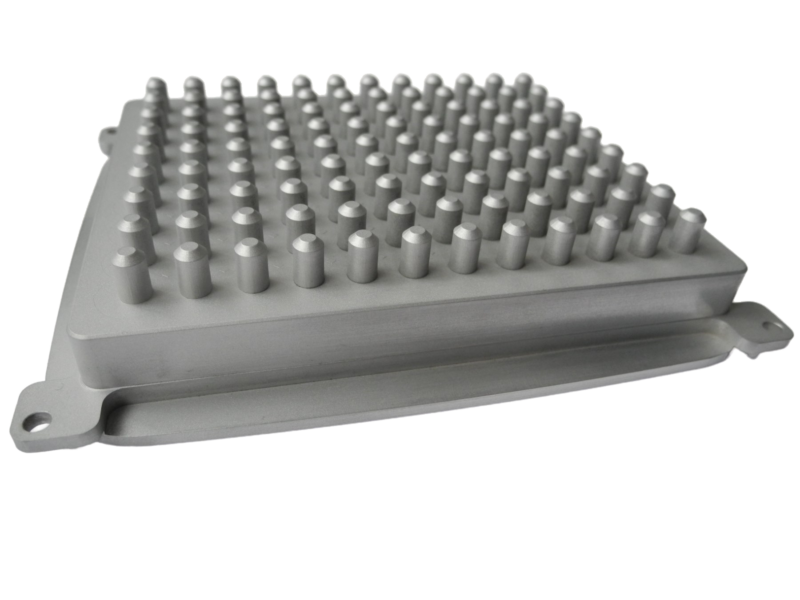

Our CNC machined parts and assemblies are used in industries such as aerospace, optics and medical technology. From miniature parts to heavyweights - we have the expertise and experience to meet your requirements.

Do you need support from the product idea to series production?

Put your trust in our decades of experience.

The following materials are in use:

- Aluminium

- Construction steel, tool steel

- Stainless steel

- Titanium alloys

- Aviation materials

- Brass, copper, bronze, etc.

- Engineering plastics

- Special materials

- Invar

Delivery of our precision parts to a wide range of industries:

- Aviation

- Space travel

- Electronics industry

- Medical technology

- Optical device manufacturing

- Research institutes and testing laboratories

- Precision engineering

- Plastics industry

- Special -/ machine manufacturing

- Lighting and energy technology

- Switchgear manufacturing

- Trade and craft businesses

- Metalwork industry

- Textile industry

- Transport businesses

- Musical instrument maker